Commercial Concrete Work in Fairfield, OH: Guide

Commercial Concrete Fairfield

Commercial concrete construction is a key element for all businesses operating within the city limits of Fairfield. This includes creating functional, long-lasting surfaces that support the day-to-day operation and heavy use of all businesses, from warehouse floors and parking areas to loading dock areas and walkways. The growing number of businesses located in Butler County requires concrete contractors who are aware of local regulatory issues, soil type, as well as Ohio’s climate issues affecting industrial operations. Quality concrete contractors will ensure compliance with ACI (American Concrete Institute) codes, while also ensuring long term performance of the concrete, which will reduce the need for costly repairs and minimize the disruption to your business. Business owners who want their property to retain its value over the years should consider hiring quality contractors to do quality concrete work.

Types of Commercial Concrete Work in Butler County

Commercial concrete professionals can provide many different types of commercial concrete services to meet the various needs of businesses in the manufacturing, retail, health care, and office industries. Of the different types of commercial concrete work performed, industrial flooring is the most prevalent due to the fact that it must be made with special concrete mix designs and finishing techniques that allow it to withstand the weight of large equipment and the chemicals involved in their use. Additionally, a significant amount of the concrete work performed involves repairing and constructing parking lots at shopping centers, office complexes, and medical facilities along the Great Miami River corridor.

Industrial and Warehouse Floors

The industrial and warehouse floors of manufacturing facilities and distribution centers are the heaviest load-bearing areas of these structures. They must be able to withstand the weight of heavy machinery, forklift traffic, and large quantities of stored products weighing in excess of 1,000 pounds per square foot. To accomplish this, most professional installations will consist of 6-8 inches of slab thickness using fiber-reinforced and specially formulated aggregate blends designed to resist abrasion and impact damage. Additional finishing techniques, such as polishing the surface, can improve the ability of the floor to reflect light while reducing its maintenance requirements. In addition to polishing the surface of the floor, some installations may also involve the use of post-tensioned construction techniques that help to reduce cracking and increase the service life of the installation to greater than 30 years.

Construction of Commercial Parking Lots

Parking lots at retail centers, office buildings, and health care facilities in Fairfield are constructed using commercial-grade concrete that far surpasses the service life and durability of asphalt. Commercial parking lots are usually installed with 6-inch-thick concrete that includes a properly functioning drainage system and joints placed according to the thermal movement of the concrete. In applications where extremely heavy-duty use is expected, such as loading docks and heavy truck access routes, the thickness of the concrete is increased to 8-10 inches with added reinforcement to support the concentrated weight of the tires of the vehicles traveling over them. A well-installed commercial parking lot should have the proper slope for adequate storm water run-off and include accessible ramps and curbs for disabled persons as defined under the Americans with Disabilities Act (ADA).

Other Specialized Commercial Concrete Work

In addition to basic concrete flooring and paving, there are several other specialized commercial concrete services that can be used to meet the individual needs of a business. One example of this is the construction of loading docks, which must be able to withstand the repeated impacts from delivery trucks and heavy freight-moving equipment. Another example of specialized commercial concrete services is the installation of sidewalks and walkways, which must be installed so that they meet the accessibility standards of the Americans with Disabilities Act (ADA), while still providing safe walking paths for employees and visitors of the business during the varying weather conditions found in Ohio.

Construction of Loading Docks and Heavy Duty Areas

Distribution centers and manufacturing facilities require reinforced concrete loading areas that are capable of resisting repeated impacts from delivery trucks and cargo-handling equipment. Most professional installations will utilize 8-12 inch thick slabs with heavy rebar reinforcement and high-strength concrete mixes with a compressive strength of greater than 4,000 psi. Professional installations should always include a drainage system to prevent the accumulation of water that could weaken the structural integrity of the loading area during freeze-thaw cycles. All professional contractors will also install suitable joint systems and edge protection to prevent chipping and spalling of the concrete due to the heavy use of the loading area.

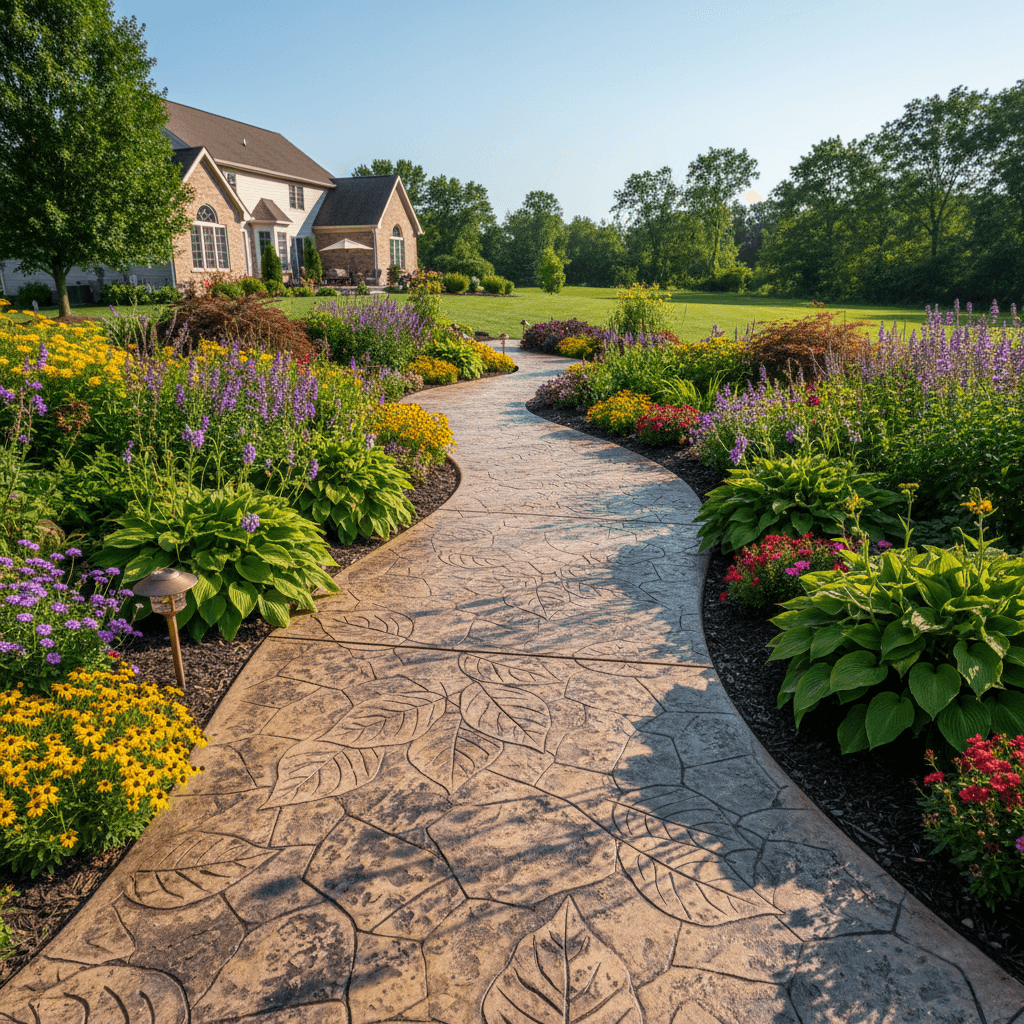

Decorative and Architectural Concrete

Increasingly, businesses are using decorative concrete elements as a way to enhance the attractiveness of their facility, while also providing a durable and low-maintenance finish. Decorative concrete elements can include stamped and colored concrete surfaces, which can be used to create attractive entrances and gathering areas that project a positive image of the company and reinforce its brand identity. In addition, polished concrete floors in retail and office settings provide a visually appealing appearance, while also offering improved durability and lower maintenance requirements than traditional flooring options. Architectural concrete elements, such as walls, planters, and accent pieces, can be integrated into a business’s building design to enhance both the aesthetics and functionality of the space.

Project Development and Permitting Requirements

For a commercial concrete project to be successful, careful planning is essential to ensure that local building codes, zoning regulations, and environmental regulations are met. The City of Fairfield Building and Zoning Division has jurisdiction over commercial construction permits for any project that meets the minimum threshold of size and scope. Professional contractors manage the permitting process, while also ensuring that the project complies with the city’s stormwater-management plan and ADA accessibility requirements.

Compliance with Local Regulations

Commercial concrete work must comply with all applicable provisions of the Ohio Building Code, local ordinances governing construction methods, materials specifications, and safety standards. Any projects that involve the construction of parking lots and/or site improvements must have a stormwater-management plan that protects the environment from the effects of stormwater runoff. Professional contractors stay up-to-date on changes in local regulations and ensure that all commercial concrete work is completed to meet or exceed code requirements. Additionally, professional contractors keep accurate records and inspect the work as it progresses to ensure that all aspects of the project are compliant with local regulations and codes.

Soil Conditions and Site Preparation

Due to the diversity of soils found in Fairfield, professional assessments of the site conditions are necessary to ensure that the site is prepared properly to achieve the desired lifespan of the concrete. For example, clay-based soils are commonly found in the vicinity of Harbin Park, and therefore would require additional preparation of the site or soil stabilization to prevent settlement and cracking of the concrete. Before the start of the project, professional contractors will perform soil-bearing tests to determine if additional preparations need to be made prior to the installation of the foundation of the project. Once the soil-bearing tests have been completed, the professional contractor will install a proper drainage system to protect against water infiltration and damage from the site’s groundwater conditions. Finally, the professional contractor will prepare the site by excavating, compacting, and installing the base course of the project to provide a solid foundation for the heavier portions of the commercial concrete project.

Factors That Influence the Costs of a Commercial Concrete Project

The costs associated with a commercial concrete project are influenced by numerous factors, including the type of application being used, the condition of the site upon which the project is being built, and the performance requirements of the project. Examples of types of commercial concrete applications include warehouse flooring, industrial flooring, and parking lots. The costs of basic warehouse flooring range from $4-8 per square foot, while the costs of industrial flooring can be as much as $10-15 per square foot, depending on the level of reinforcement and surface treatment being applied. The costs of commercial parking lots can range from $6-12 per square foot, depending on the thickness of the pavement and whether or not accessibility features such as curb cuts and wheelchair-accessible ramps are included.

Materials and Labor Costs Associated with Commercial Concrete Work

As previously mentioned, high-strength concrete mixes used in commercial concrete applications are approximately 20-40 percent more expensive than the residential-grade mix; however, high-strength concrete offers significantly longer performance and durability than residential-grade mixes. Labor costs represent 40-60 percent of the overall cost of a commercial concrete project, taking into account the specialized equipment and training necessary for the installation of commercial concrete projects. High-quality contractors utilize the latest technology, including laser screeds, power trowels, and concrete pumps, to ensure accurate and efficient placement and finishing of the concrete.

Value of Long-Term Performance

A commercial concrete installation provides long-term value for a business in the form of decreased maintenance costs and increased service life when compared to other materials that can be used for commercial applications. Professional installations of commercial concrete are generally maintenance-free for 20-30 years, requiring only periodic joint sealing and surface cleaning. By having fewer interruptions to operations and less need for replacement parts and materials, businesses are able to maintain a professional appearance that promotes customer confidence and employee satisfaction. Additionally, energy-efficient features, such as light-colored surfaces, can reduce lighting costs and contribute to the sustainability goals of the business.

Performance Standards for Commercial Concrete Installations

To ensure that the performance standards are maintained for commercial concrete installations, all professional contractors follow strict quality-control protocols. These protocols are developed to ensure consistency of results and performance of the commercial concrete installation. The American Concrete Institute (ACI) establishes industry standards for commercial concrete installations regarding mix design, placement, and finishing techniques, and other parameters specific to commercial applications. Professional contractors maintain detailed records of material specifications, testing results, and installation procedures that support warranties and future maintenance planning for the commercial concrete installation.

Protocols for Testing and Inspections

All commercial concrete installations must undergo comprehensive testing to ensure that the performance of the installation meets the specified requirements of the commercial application. Professional contractors coordinate the testing of the concrete installation with certified testing laboratories to ensure that the testing meets the requirements of the applicable codes and standards. Depending on the specific commercial application, additional testing may be required, such as testing for floor flatness (F-number) for warehouse applications, or testing for permeability for chemical-resistant applications. Proper documentation is maintained to confirm the quality of the commercial concrete installation and to support warranty claims and future maintenance of the installation.

Criteria Used to Evaluate Contractor Capability

To select a contractor capable of completing a commercial concrete project successfully, a business must evaluate the contractor’s experience and qualifications in commercial concrete applications. Successful commercial concrete contractors must have the necessary licenses, insurance coverage, and certifications to complete commercial concrete projects in the state of Ohio. Professional contractors must also have the specialized equipment and technical expertise to complete complex commercial concrete installations, and must provide comprehensive project management from the initial planning stages through completion of the project. Business owners should seek references from previous commercial concrete projects completed by the contractor, and look for industry certification to assess the contractor’s capability and reliability for demanding commercial applications.

Maintenance and Life Cycle Management of Commercial Concrete Installations

Maintaining the performance and appearance of commercial concrete installations is essential to maximize the return on investment for a business. A proactive maintenance program helps to minimize costs and disruptions to operations caused by unexpected failures of the commercial concrete installation. Regular inspections will enable early detection and correction of minor problems that may become costly repairs requiring extensive reconstruction of the commercial concrete installation. Professional maintenance services provided for commercial concrete installations include sealing the joints and cracks, and applying surface treatments to preserve the structural integrity and aesthetic appearance of the commercial concrete installation throughout its extended service life.

Programs for Preventive Maintenance of Commercial Concrete Installations

Business owners can establish preventive-maintenance programs to protect their commercial concrete installations. An annual inspection schedule can help detect small problems before they become larger, more costly problems. Sealing the joints and cracks of the commercial concrete installation every 3-5 years can help prevent water from entering the structure and causing damage. Cleaning the surface of the commercial concrete installation as needed will help maintain its professional appearance and provide a safe walking path for employees and visitors of the business during all weather conditions present in Ohio.

Commercial Concrete Work Provides Valuable Infrastructure Support to Businesses

Investments in commercial concrete work represent important investments for businesses in terms of meeting the needs of their customers, improving the working conditions of their employees, and increasing productivity while decreasing costs. Professional contractors can provide the specialized expertise that is necessary to ensure that commercial concrete work is done in compliance with all applicable laws and regulations, is done correctly, and will last for decades. Businesses located in Butler County can rely on the comprehensive commercial concrete services of Fairfield Concrete Contractors, including planning, installation, and maintenance, to provide a solid foundation for future growth and success.