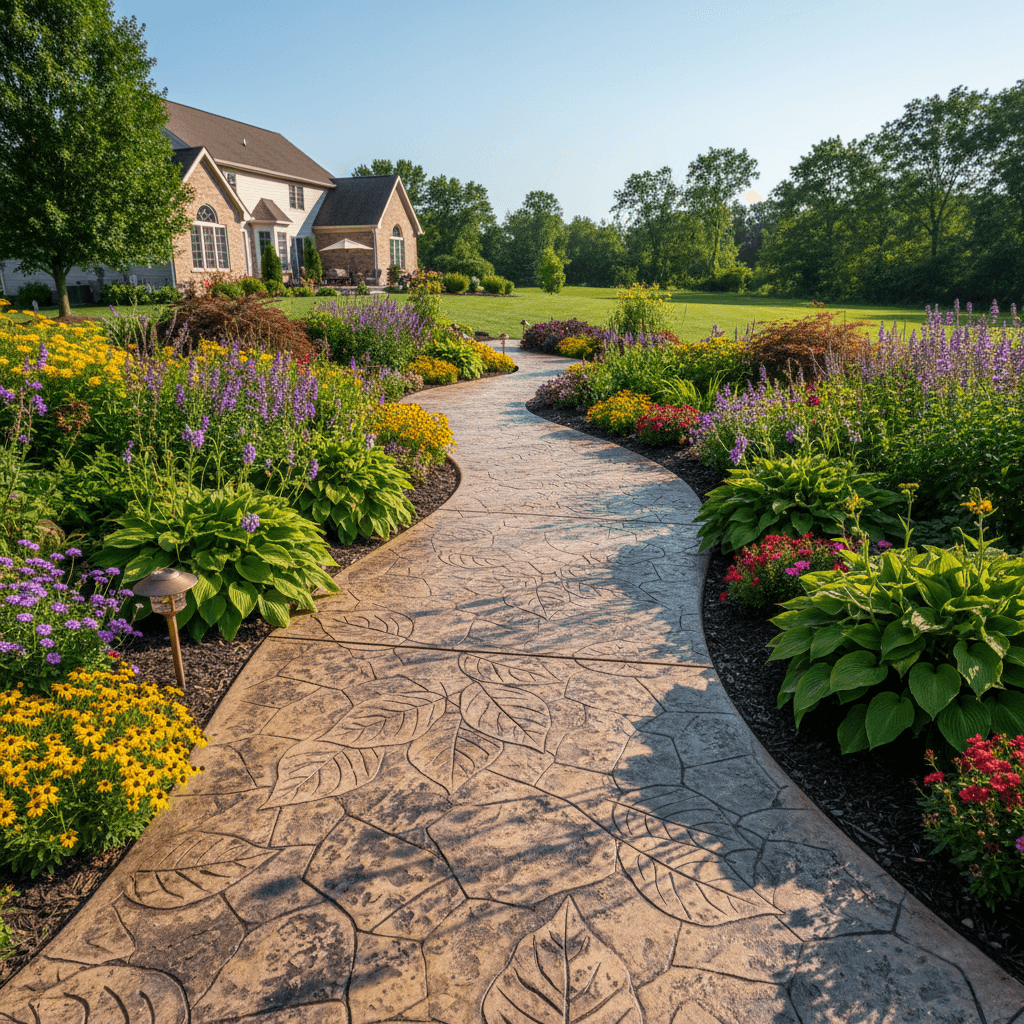

How to Pick Quality Stamped Concrete in Fairfield, OH

Stamped Concrete Fairfield

The difference between a professional stamped concrete installation and a poor-quality one lies in understanding the quality of the materials. High-quality materials produce beautiful surfaces that last for years, while low-quality materials will fade faster, crack sooner, and degrade the surface of the concrete much faster than a higher-quality product. Professionals in Fairfield use high-end materials as they are designed to withstand the extreme climate changes associated with the State of Ohio (freeze-thaw cycles and temperature swings). Although high-end materials can be expensive at first, they provide a great deal of value when it comes to longevity and lower maintenance costs over time. In fact, homeowners who invest in high-end materials can expect many decades of dependable performance out of their decorative concrete surfaces.

Essential Components of High-Quality Concrete Mix Design

Stamped concrete that will last is built upon a solidly constructed and well-engineered concrete mix design, which uses the correct proportion of cement, aggregate, and water. A premium Portland cement is stronger than, and consistently performs better than, a less expensive alternative. Well-graded aggregates create void-free, dense concrete that does not allow water to penetrate and minimizes potential structural weaknesses.

Portland Cement Specifications and Quality

For residential applications in Butler County, Type I/II Portland cement provides the best combination of strength development and sulfate resistance. High-quality Portland cement has a consistent chemical makeup that ensures predictable hydration rates and final strength characteristics. High-quality manufacturers have quality-control measures that ensure there is no variation in different batches of cement. In addition, some cement manufacturers use fly ash (a by-product of coal-fired power plants) in their cement, which can increase the workability of the mix while reducing the environmental impact of the product.

Selection and Grading of Aggregates

Aggregates that are well-graded and have the right amount of distribution will produce concrete matrices that have the fewest number of voids and, therefore, will be the strongest. Clean-surfaced, angular-shaped coarse aggregates will produce the strongest bonds with the cement paste. Fine aggregates should meet the ASTM C33 specification for grading and will provide the best workability when placing and finishing the concrete. Local aggregates that come from quarries near Fairfield usually produce the most consistent quality and the lowest cost of transportation.

Color Hardeners: The Secret to Lasting and Vibrant Color

Top-quality color hardeners contain top-grade iron oxide pigments that will not fade due to ultraviolet (UV) light and retain their color for decades. High-quality color hardeners also have the correct ratio of cement, silica sand, and pigments to form a thick, dense layer that is resistant to abrasions and weathering. Top-quality color hardeners apply evenly to the surface of the concrete and provide a consistent look throughout the entire surface.

Iron Oxide Pigment Quality and Light Fastness

Top-quality iron oxide pigments have high light-fastness ratings that do not degrade color over time due to sunlight exposure. High-quality iron oxide pigments are chemically stable in an alkaline environment and do not bleed or react with other mixing ingredients. Manufacturers of high-quality pigments use synthetic iron oxides instead of naturally occurring minerals; they can consistently match colors between different batches. While these pigments are significantly more expensive than lesser quality pigments, they will provide the longest life-span and best color retention.

Composition of Hardener and Performance

High-quality hardeners have the optimal ratio of cement to aggregate to produce strong, dense layers on the surface of the concrete without sacrificing workability. High-quality formulations include special silica aggregates to improve surface hardness and resistance to abrasion. Top-quality hardeners include fiber reinforcement to reduce cracking of the surface and increase the resistance to impacts. Even particle-size distributions will provide uniform coating and will help avoid application problems with the installation.

Release Agents: Importance for the Definition of Patterns and Surface Protection

Release agents are used as a bond breaker and second coloring system to define patterns and add visual depth to the surface of the stamped concrete. Top-quality powder releases contain hydrophobic agents that will prevent the stamp from sticking to the freshly placed concrete while adding a slight antique effect to the texture of the surface. Top-quality liquid releases are easier to apply and produce little to no dust, while producing good bond breaking for even the most intricate designs.

Characteristics of Powdered Releases

Top-quality powdered releases contain specifically developed moisture-barrier agents that will prevent the stamp from coming into contact with the freshly placed surface of the concrete. Top-quality powdered releases also contain weather-resistant pigments that will create permanent accent colors in the recessed areas of the design. Top-quality powdered releases will have a consistent particle-size distribution that will evenly spread and will not clump together or cause application problems. High-quality powdered releases need to be applied at very low volumes while still providing the highest level of performance and reducing the volume of waste and cleaning required.

Liquid Release Systems

Top-quality liquid releases provide the best way to control dust generated during the application of stamped concrete. High-quality liquid releases will coat the surface of the concrete evenly and will provide the same level of coverage as powdered releases over large areas. Top-quality liquid releases penetrate the surface of the concrete evenly and do not leave behind films that will interfere with the adhesion of subsequent coats of sealer. Once applied to the surface of the concrete, high-quality liquid releases evaporate quickly and leave behind very little residue that would need to be removed before the finishing operation. High-quality liquid releases perform exceptionally well in interior applications or in applications located close to Village Green, OH, where controlling dust is extremely important.

Top Quality Stamping Tools and Equipment

High-quality stamping tools produce realistic textures that mimic the texture of natural materials such as stone, brick, and wood. High-quality polyurethane stamping tools have higher tear-strengths and greater flexibility than those of lower quality, allowing for precise and undistorted pattern transfer. High-quality stamps will consistently produce accurate and realistic textures over thousands of applications and are far superior to poor-quality tools that will fail quickly and provide unpredictable results.

Construction and Material of Stamp

High-quality stamps are made from high-density polyurethane compounds that are resistant to wear and chemical degradation from the alkalinity of the concrete. High-quality stamps are produced with precision-molded textures from actual material samples to provide a realistic appearance and to accurately represent the details of the original material. High-quality construction of stamps bonds the individual layers of the stamps together so that the stamps do not delaminate and lose their pattern accuracy. High-quality stamps are more expensive than low-quality stamps but provide professional results and justify the cost of ownership.

Texture Skins and Detail Tools

High-quality texture skins provide additional detail to the edges of the patterns and in areas where regular stamps cannot effectively provide detail. High-quality texture skins are flexible enough to conform to irregular surfaces while retaining the ability to provide consistent texture transfer. High-quality texture skins are durable and will withstand being torn during the application and cleaning process, increasing the lifespan of the tool. These specialized tools allow contractors to create seamless transitions between complex designs in and around Harbin Park and surrounding neighborhoods.

Sealers for Stamped Concrete

High-quality concrete sealers protect the surfaces of the stamped concrete from penetrating moisture, stains, and UV-degradation while improving color vibrancy and definition of patterns. High-quality sealers will adhere to the surface of the concrete without peeling or delaminating due to typical traffic in Ohio. High-quality sealers remain flexible and will accommodate thermal expansion and contraction caused by seasonal temperature changes.

Acrylic Sealer Technologies

High-quality acrylic sealers are made up of superior polymer chains that will provide long-term protection and improved durability compared to standard formulations. High-quality acrylic sealers contain UV-stabilizers that will prevent the yellowing and degradation of the sealed surface due to prolonged exposure to sunlight. High-quality acrylic sealers are available in a variety of sheens, from matte to high-gloss finishes, that will complement a wide range of architectural styles found in Butler County. High-quality acrylic sealers will require reapplication approximately every 2-3 years to maintain the desired level of protection and appearance.

Solvent-Based vs. Water-Based Sealants

Solvent-based sealers will penetrate further into the surface of the concrete and provide increased protection and color enhancement of the design elements. Solvent-based sealers will provide the best protection and color enhancement for designs with many recessed areas. Water-based sealers are easier to apply and clean up, and comply with local environmental regulations. Solvent-based sealers will provide the best protection against freeze-thaw conditions; however, water-based sealers will provide adequate protection for most residential applications. Contractors will choose the type of sealer to be used based on the specific needs of each project.

Material Testing and Quality Control

To provide professional-quality installations, it is necessary to implement complete quality-control measures to ensure the materials selected meet the specified requirements and performance characteristics. Routine testing will confirm that the concrete meets the design requirements and remains workable during the placement and finishing phases. All quality contractors maintain records of the source of the materials and the results of the testing to support warranty claims and future references.

Testing Procedures for Concrete

Standardized testing procedures include slump testing to determine the workability of the concrete, air-content testing to assess the resistance to freeze-thaw conditions, and compression-strength testing to verify the design requirements. Monitoring of temperatures will ensure proper curing conditions, and scheduling of the installation will occur regardless of the changing weather conditions. All quality contractors record all test results to prove compliance with the project specifications and warranty requirements. Implementing these quality-control measures will prevent costly problems and ensure the performance of the installed stamped concrete for many years to come in the Great Miami River area.

Selecting the Best Materials to Ensure Long-Term Results

Using high-quality materials will create a stamped concrete installation that will increase property values while providing decades of dependable performance. Selecting the best quality materials requires knowledge of the difference in the quality of premium and standard-quality products. Fairfield Concrete Contractors has established relationships with the leading manufacturers of high-quality materials to ensure our customers receive the best possible materials to provide superior results that exceed the customer’s expectations in Butler County and surrounding areas.