The Best Time of Year for Pouring Concrete in Fairfield, OH

Pouring Concrete Fairfield

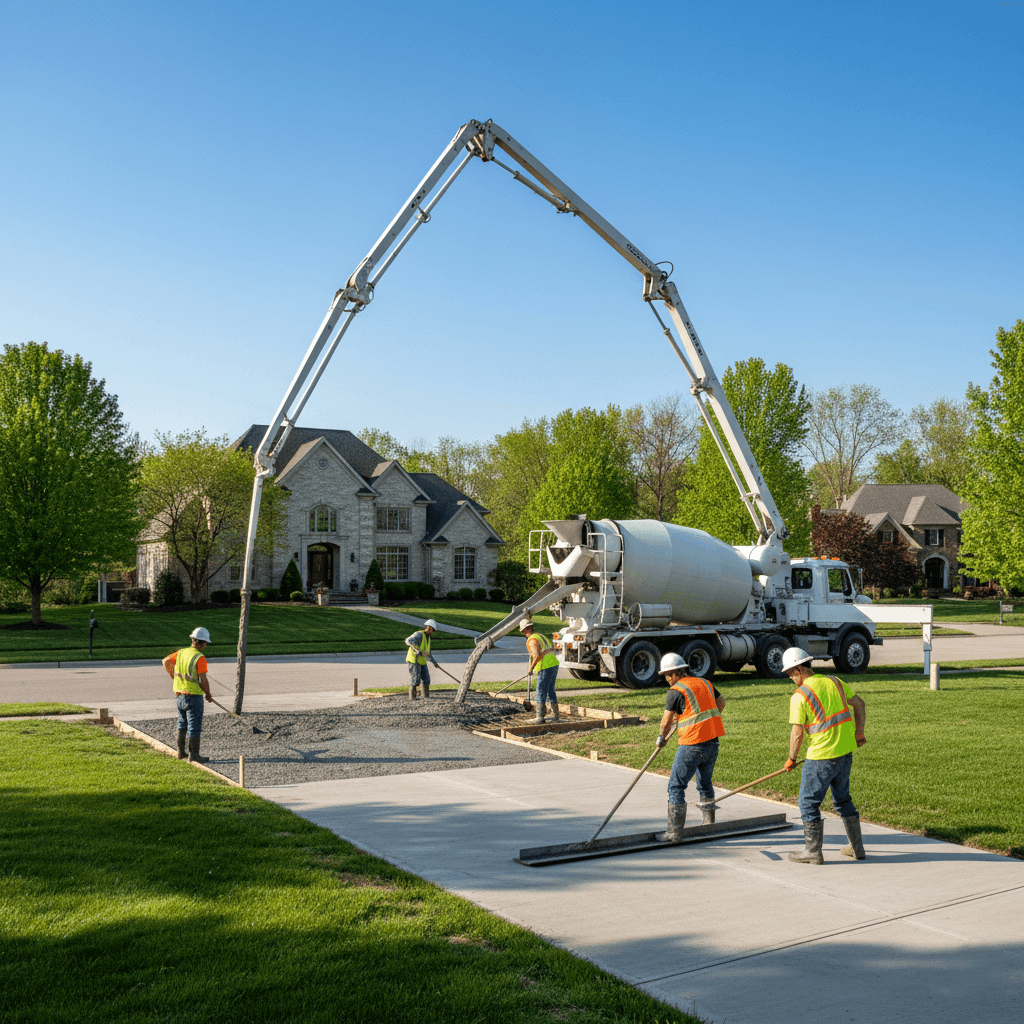

Successful concrete installation in Fairfield requires timing so that all elements are placed at the appropriate times to allow the proper curing and long-term durability of the final product. The continental climate of Ohio has its own unique seasonal challenges, which can affect when you place your concrete, and the temperatures, humidity, and precipitation levels will have a direct impact on the strength and quality of the final project. Contractors who do this professionally know that making good choices about when to place your concrete helps to avoid many costly mistakes, as well as ensures that your structure will be strong enough and aesthetically pleasing. A contractor must consider many different elements when determining when to schedule their concrete placements, such as temperature ranges, the amount of rain and snow expected in the area over a period of days or weeks, and the amount of precipitation Butler County is likely to receive at that time of the year. A smart contractor will make good choices regarding the timing of the placement of their concrete to ensure that their investment is protected, and the result will provide a high-quality finish that will hold up to the changing conditions of Ohio’s climate.

Optimal Temperature Ranges for Pouring Concrete

Many professionals agree that the ideal temperature for installing new concrete is between 40°F (4°C) and 60°F (15.5°C). This temperature range provides ideal curing conditions and does not require the contractor to take any protective measures.

In reality, the ideal temperature for doing concrete work lies between 40°F (4°C) and 60°F (15.5°C), allowing for the most effective natural curing conditions, and thus supporting the chemical reaction of hydration of concrete.

Pouring concrete at temperatures lower than 40°F slows down the chemical reactions that strengthen the concrete and produce a weaker concrete that has less desirable strength properties. On the other hand, air temperatures greater than 77°F (25°C) result in rapid curing, leading to surface defects and cracking, as well as reduced durability and compromised long-term performance.

Impact of Temperature on Concrete Quality

Two primary factors influence the ideal temperature for pouring concrete: one being the curing process of the concrete, and the other being the prevention of extreme conditions that can contribute to shrinkage and cracking problems. Curing concrete at temperatures lower than freezing causes water within the concrete to freeze and expand, causing internal damage to the concrete, which may not be apparent at first but significantly reduces the overall structural integrity of the building.

Extreme heat during the curing process accelerates the curing process and can lead to surface cracking if the contractor does not implement specialized techniques to manage this rapid curing. There is an optimal temperature for curing concrete, which falls within the range of 70°F (21.1°C) and 80°F (27°C); however, once the temperature reaches 90°F (32.2°C), the contractor must modify their installation procedures to prevent rapid surface drying and thermal stresses.

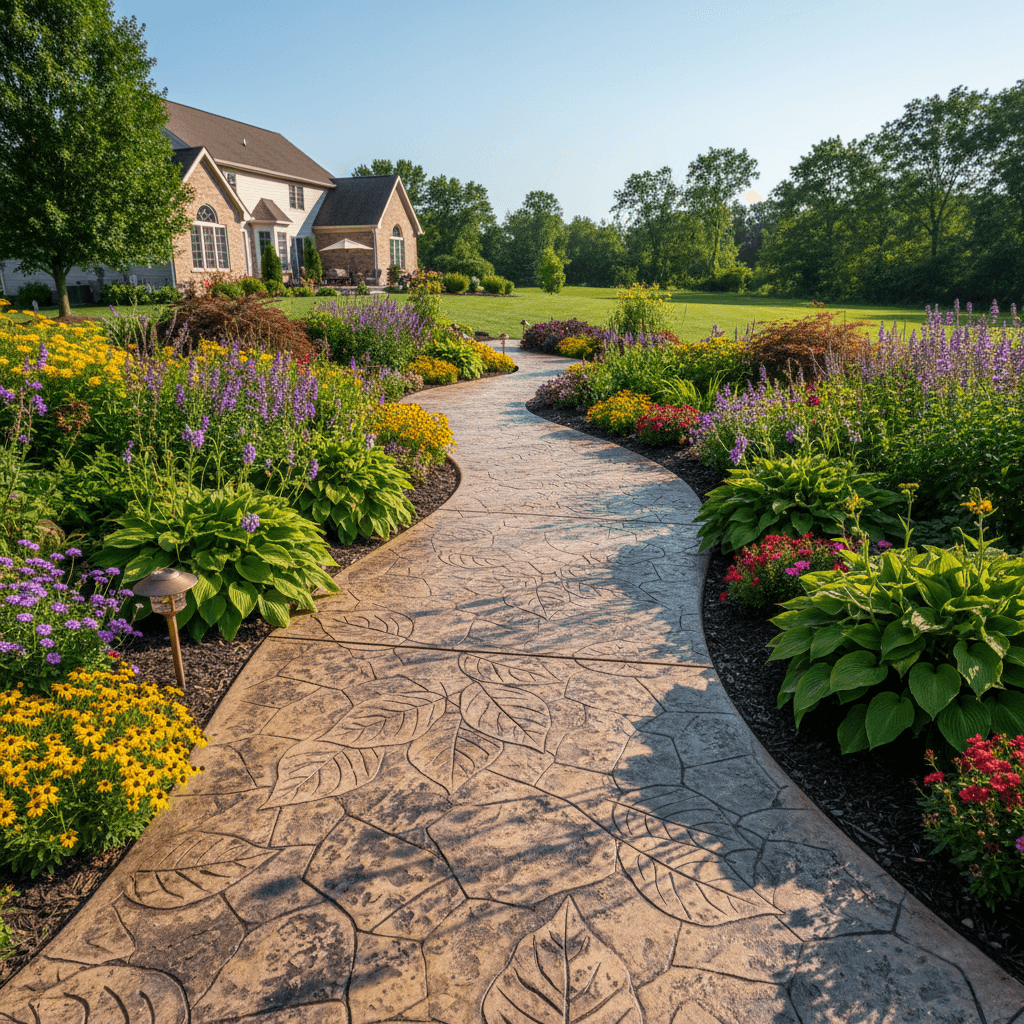

Spring: The Ideal Time to Perform Concrete Work

Spring is typically an ideal time to install new concrete because the temperatures begin to stabilize after the harsh conditions of winter. During the spring months, the temperature fluctuates between 50°F (10°C) and 70°F (21.1°C), which provides an ideal environment for curing concrete without the need for special heating or cooling.

It is also recommended to perform all of your concrete work during the warmer months, specifically from mid-April to mid-October, as these months provide the most beneficial natural curing environments for your new concrete. Additionally, these months will provide the greatest opportunity for you to obtain the desired strength and durability from your new concrete while also making the mixing and pouring processes much easier for your installation crew.

Advantages of Spring Weather Patterns

The weather patterns associated with spring in Fairfield typically consist of stable conditions and moderate humidity levels, which facilitate optimal hydration of the concrete and minimize the amount of excess moisture lost by the concrete.

Consistent temperatures during the spring months significantly decrease the risk of thermal stress that can develop during the early stages of the curing process, which is critical to prevent cracking.

Additionally, the longer days of the spring provide your installation crew with extended periods of daylight to complete more complex projects while minimizing the possibility of experiencing the extreme temperatures of both summer and winter. As such, professional contractors can establish their own schedules to install new concrete during the most favorable morning and afternoon temperatures while maintaining the same level of productivity and efficiency throughout the entire duration of the project.

Fall: A Suitable Alternative to Spring for Installation

Similar to spring, fall is a suitable alternative to spring for performing new concrete installations due to the mild temperatures and low precipitation that prevail throughout Butler County during the late fall months.

September through November typically consists of moderate weather patterns that promote the successful installation of new concrete while minimizing the likelihood of unforeseen weather-related complications.

However, contractors need to remain vigilant and monitor weather forecasts closely, as a sudden cold front or snowstorm can develop as early as September in Ohio and potentially disrupt the curing process of the new concrete. Furthermore, in cases where the installation extends into November, the contractor may be required to utilize cold-weather protection to maintain adequate curing times prior to the onset of winter.

Contingency Planning for Late-fall Installation

As mentioned previously, the onset of winter in Ohio can develop as early as September, necessitating the development of contingency plans for any fall installations that extend into the month of November. These contingency plans should address potential weather-related delays and provide the ability for the contractor to adjust their schedule accordingly to accommodate changing weather conditions.

Contractors who employ flexible scheduling and planning practices, similar to those employed by professional contractors, can mitigate the impact of adverse weather conditions on the completion timeline of a project and ultimately provide superior results.

Challenges of Performing Concrete Work in the Summer Months

While the majority of the year is relatively conducive to performing concrete work in Ohio, the extreme temperatures prevalent during the summer months can present significant challenges to the contractor, particularly with respect to the accelerated curing process that occurs in high temperatures.

High temperatures during the summer months accelerate the curing process of the concrete, which can create difficulties in completing the finishing process and potentially introduce surface defects and cracks in the concrete. To overcome these challenges, contractors must employ various techniques, such as the utilization of chilled mixing water, early morning or evening placement of the concrete, and implementation of accelerated curing procedures.

Strategies for Managing Extreme Heat

To complete concrete work in extreme heat, professional contractors employ several different strategies, including the scheduling of placements during cooler hours of the day. By conducting placements during the early morning and evening hours, contractors can avoid the elevated temperatures commonly experienced during the middle of the day and thus reduce the risk of rapid surface drying and thermal cracking.

In addition to employing specialized placement techniques, contractors may also utilize specialized materials, such as retarders, chilled water, and accelerated curing compounds, to compensate for the adverse effects of extreme heat on the curing process and maintain the structural integrity of the concrete.

Limitations Associated with Winter Installations

Installations of new concrete in Ohio during the winter months are subject to numerous limitations, primarily associated with the necessity to protect the concrete from freezing during the initial 24-48-hour curing period. In order to prevent damage caused by freezing, the temperature of the concrete must remain above 50°F (10°C) for at least 48 hours after placement to enable the concrete to achieve sufficient strength prior to exposure to freezing conditions.

Performing new concrete installations during the winter months in Butler County significantly increases the cost of the project due to heating requirements, insulation materials, and increased curing protection periods.

Most contractors in Butler County cease all exterior concrete work during the months of December through February due to the uncertainty of weather conditions and the expense associated with cold-weather protection.

Requirements for Freeze Protection

Protection of the concrete from freezing is paramount during the initial 24-48-hour curing period in order to achieve the design strength of the concrete and to prevent permanent damage. The application of cold-weather protection measures becomes essential during this initial 24-48-hour period when the ambient temperature drops below 40°F (4°C).

Heated enclosures, ground thawing, and continuous temperature monitoring are among the common methods used to protect concrete from freezing during the curing process.

Common Cold Weather Protection Methods

Among the common cold-weather protection methods used by contractors to protect newly placed concrete from freezing are the use of heated aggregates, warmed-up mixing water, and the application of insulated blankets or heated enclosures directly on top of the newly installed concrete. However, these additional requirements and protections add significant complexity to the project and increase the overall cost of the project, as well as prolong the project completion date compared to projects installed under favorable weather conditions.

Seasonal Scheduling Strategies for Concrete Projects

Effective planning for a concrete project requires consideration of seasonal weather patterns and contractor availability throughout Butler County. Spring and fall are typically the highest demand seasons for concrete service providers. Property owners should plan for their concrete projects at least 2-3 months before the ideal installation dates to secure the desired contractor and installation date.

This advanced planning allows for the necessary time to prepare the site for the project, acquire permits and approvals, and schedule the installation during the most favorable weather conditions for producing high-quality concrete.

Monitoring and Adjustments Based on Weather Forecast

Modern weather forecasting technologies now provide accurate predictions of temperature and precipitation patterns that affect the decision-making process related to the installation of new concrete. Contractors must continue to monitor extended weather forecasts to determine the optimal installation windows and remain flexible enough to adjust their schedule based on changes in weather conditions.

To effectively install high-quality concrete, a contractor must have established backup installation dates and contingency plans for weather-related delays. Experienced contractors develop flexible scheduling practices that prioritize the quality of the concrete over the rigidity of a project schedule, ensuring the delivery of exceptional results despite seasonal challenges.

Fairfield Concrete Contractors understands the importance of selecting the right time to install new concrete to maximize the outcome in Butler County’s challenging climatic conditions. Our staff of experienced professionals continues to monitor weather conditions throughout the year to assist our clients in identifying the best possible installation windows for their specific projects, utilizing decades of local experience combined with established practices that optimize concrete performance. Whether installing concrete in the spring and taking advantage of the ideal curing conditions, or installing in the fall and completing the installation before the arrival of winter weather, we guide our clients in the selection of the most favorable installation times for their projects, and provide the quality construction practices and professional installation services necessary to protect our clients’ investments.